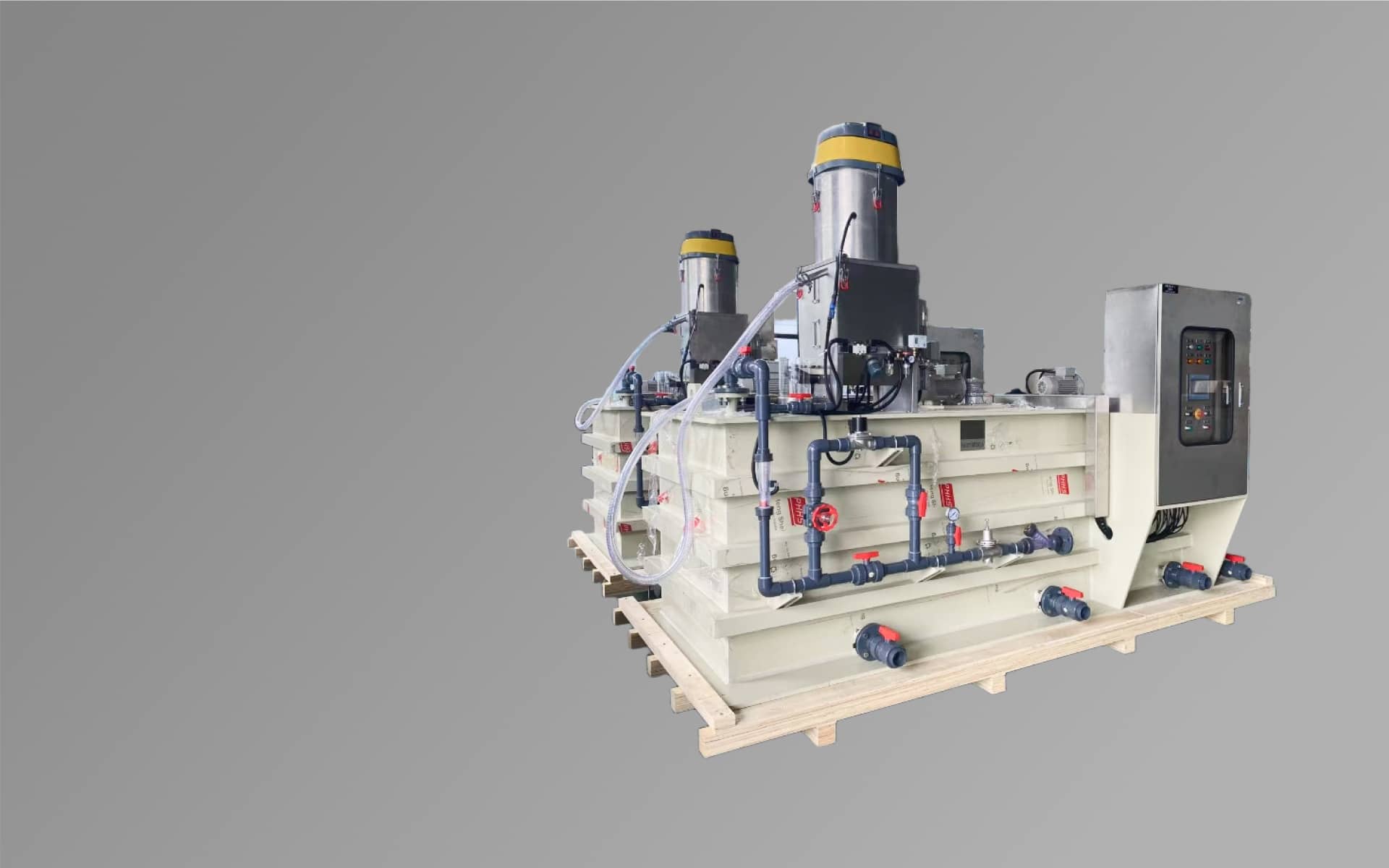

Flocculant Preparation Device

The flocculant preparation device (also known as automatic foaming machine, automatic dosing device) is designed specifically for the dissolution, maturation, and dosing of polymer flocculants (such as PAM), solving the problems of low efficiency, poor accuracy, and easy agglomeration of traditional manual dosing. The system achieves quantitative addition of dry powder, graded preparation and storage of solutions through a fully automated process, which is widely applicable in fields such as sewage treatment, drinking water purification, sludge dewatering, paper-making/petrochemical industry, etc., ensuring 100% dissolution efficiency of chemicals and precise and controllable dosage.

Product Structure

Dry powder dosing system

- Feeding hopper: equipped with moisture-proof heating coil .

- Variable frequency screw pump&metering screw: supporting stable feeding of dry powder .

- Liquid medicine mixer: made of SUS304 material, integrated design, achieving preliminary mixing of dry powder and water.

Three tank reaction system

- reparation tank: equipped with solenoid valves, flow meters, and low-speed agitators. Quantitatively mix water with dry powder.

- Maturation tank: Use a low-speed stirrer to extend the reaction time and ensure that the reagent is fully hydrated.

- Storage tank: equipped with SUS304 connecting rod float level gauge to achieve liquid level linkage control.

Control system

Core functions

Three water level control (low water level shutdown/medium water level start water inlet/high water level stop adding powder and water).

Support PLC expansion (optional), compatible with remote/on-site/automatic modes. Control objects: mixer, float ball, heating ring, dosing pump, etc.

Working Process

Water inlet trigger: When the liquid level in the storage tank drops to a low level, the solenoid valve opens for water inlet.

Dry powder addition: The flow meter is linked to a variable frequency screw pump to add dry powder in proportion .

Graded mixing:

Preparation tank: Mix dry powder with water initially.

Maturation tank: Extend the reaction time to the set value.

Storage and protection:

Stop adding when the liquid level in the storage tank reaches a high level, and continue to prevent sedimentation with the mixer.

Equipped with overflow protection and air transport protection mechanisms.

Product Features

High degree of automation, fully automated operation, saving labor.

Variable frequency screw pump+flow meter achieve high dosing accuracy control, supporting concentration customization.

Strong durability, all SUS304/316 stainless steel body, imported mixer/solenoid valve, strong corrosion resistance.

Support single tank/double tanks modification, expandable PLC control, vacuum suction machine, touch screen and other optional functions.

Easy to maintain, modular design, no basic installation requirements, maintenance only requires regular cleaning of the tank body and inspection of sealing.

Strong safety guarantee, anti caking heating coil, anti clogging Y-shaped filter, dual protection against idling/overflow.

Specifications and models

| Model | Capacity | Volume | Power | Weight | Pipe dimensions | External dimensions (mm) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| (L/H) | (L) | (kW) | (kg) | Inlet pipe diameter | Outlet pipe diameter | Vent pipe diameter | L | W | H | Tank height | |

| PY3-1000 | 1000 | 45 | 1.8 | 470 | DN25 | DN32 | DN32 | 1710 | 1125 | 1710 | 900 |

| PY3-1500 | 1500 | 45 | 1.8 | 580 | DN25 | DN40 | DN40 | 1830 | 1175 | 1710 | 900 |

| PY3-2000 | 2000 | 45 | 1.8 | 660 | DN25 | DN40 | DN40 | 2470 | 1180 | 1710 | 900 |

| PY3-3000 | 3000 | 50 | 1.8 | 850 | DN32 | DN50 | DN40 | 2490 | 1400 | 1910 | 1120 |

| PY3-4000 | 4000 | 60 | 2.4 | 1080 | DN40 | DN50 | DN40 | 3050 | 1475 | 1910 | 1100 |

| PY3-5000 | 5000 | 60 | 2.4 | 1150 | DN50 | DN50 | DN50 | 3690 | 1525 | 1910 | 1100 |

| PY3-6000 | 6000 | 60 | 2.4 | 1270 | DN50 | DN50 | DN50 | 3690 | 1775 | 1910 | 1100 |

| PY3-8000 | 8000 | 75 | 3.2 | 1500 | DN50 | DN50 | DN50 | 4880 | 1850 | 1930 | 1100 |

ISO9001

ISO9001